|

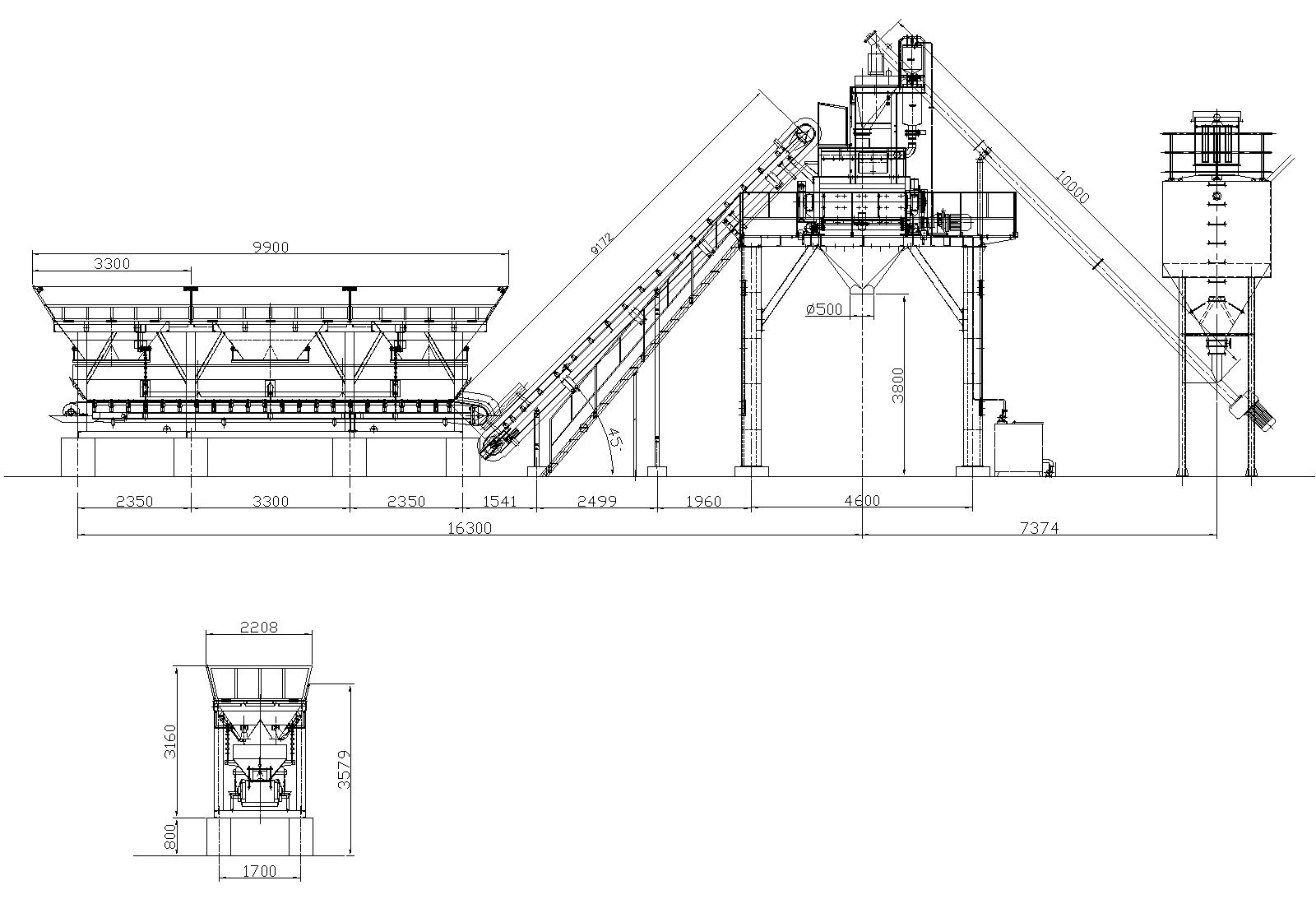

. The easily-damaged parts could last for long time, convenient to operate and maintain. It applied the latest design for electronic weighing, computer control and digital display. The electronic weighing system has a buffer device and automatic volume compensation with high accuracy. The batching machine sand and gravel feeding system applied inclined belt with great width, the maintenance walkways is installed. It is the ideal choice for producing high-quality concrete. . The easily-damaged parts could last for long time, convenient to operate and maintain. It applied the latest design for electronic weighing, computer control and digital display. The electronic weighing system has a buffer device and automatic volume compensation with high accuracy. The batching machine sand and gravel feeding system applied inclined belt with great width, the maintenance walkways is installed. It is the ideal choice for producing high-quality concrete.

| Model |

HZS50 |

| Specification |

Unit |

Value |

| Productivity |

m3/h |

50 |

| Capacity of Mixer |

m3 |

1 |

| Mixer Power |

kw |

37 |

| Discharge Height |

m |

3.8(for customers choice) |

| Aggregate Bin |

Quantity |

3 |

| Aggregate Bin Capacity |

m3 |

1.6 |

| Max. Weighing Value of aggregate |

kg |

1000 |

| Max. Weighing Value of cement |

kg |

800 |

| Max. Weighing Value of water |

kg |

350 |

| Max. Weighing Value of additive |

kg |

30 |

| Aggregate Measuring Accuracy |

% |

2 |

| Water Measuring Accuracy |

% |

1 |

| Cement Measuring Accuracy |

% |

1 |

| Additive Measuring Accuracy |

% |

1 |

| Cement Silo |

_ |

Optional |

| Cement Screw Conveyor |

_ |

Optional |

| Cement Silo Capicity |

_ |

Optional |

| Control Mode |

_ |

Auto/Semi control |

|